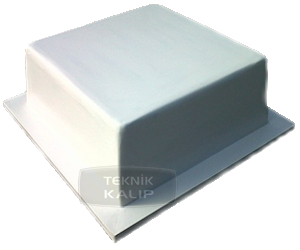

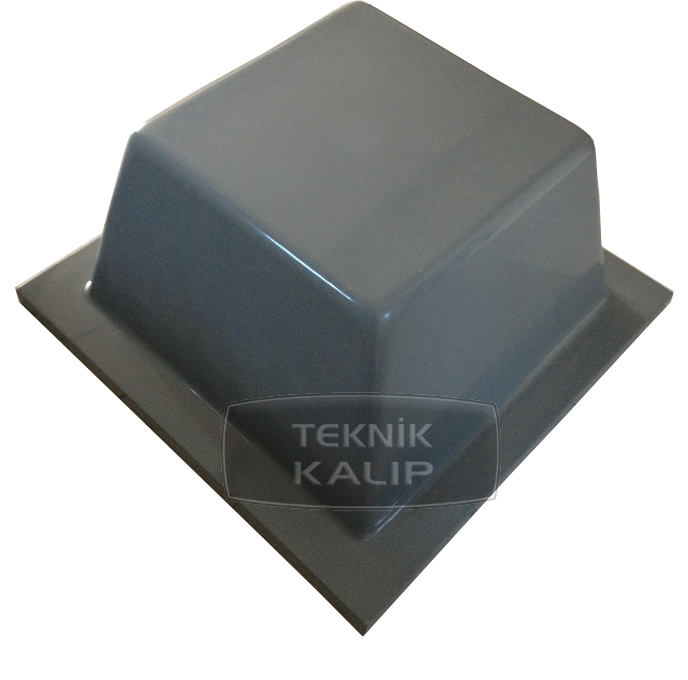

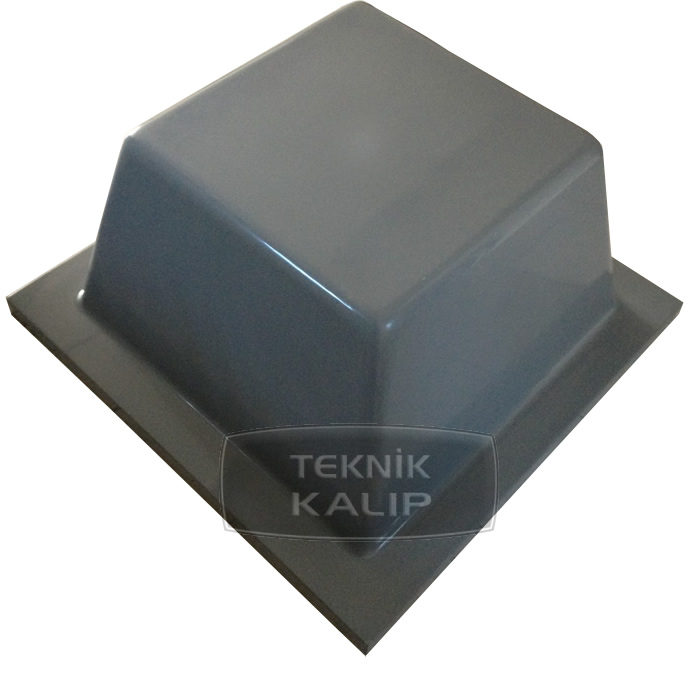

WAFFLE MOULDS – AREA OF USAGE

Waffle moulds are generally used for the projects those have a wide spanning area of more than 8m. Buildings such as, hospitals, shopping malls, multi storey car parks, conference rooms, industrial facilities, wide logistics areas etc.The waffle moulds are generally in small square form and offers designers a comprehensive choice of fiberglass waffle moulds for constructing two-way spanning floors for a very high loadbearing. By means of waffle design concrete slabs easily bears its own load…

More…

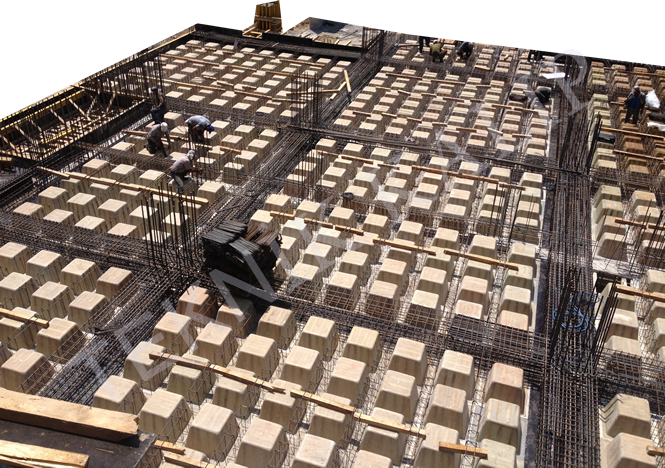

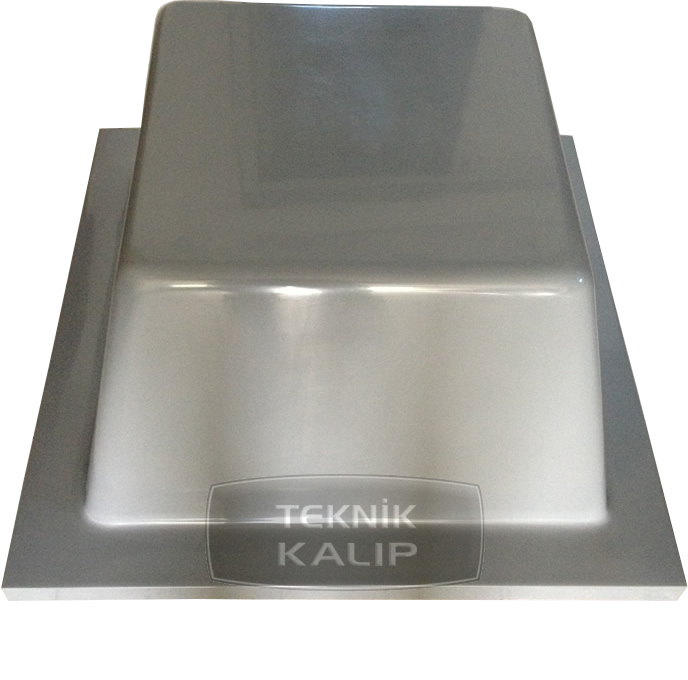

INSTALLATION AND APPLICATION

Waffle moulds can be used with all types of scaffolding system. But the spindles with U heads advised. After the assembly of base plates for main beams, H20 beams must be placed on slab area. H20 beams must be placed according to waffle dimensions and grid area. Then waffle moulds are ready to be placed on H20 beams. A suitable mould release agent applied on the mould surfaces after the placement. Then iron structure can be formed by spinning. The final stage is concreting…

More…

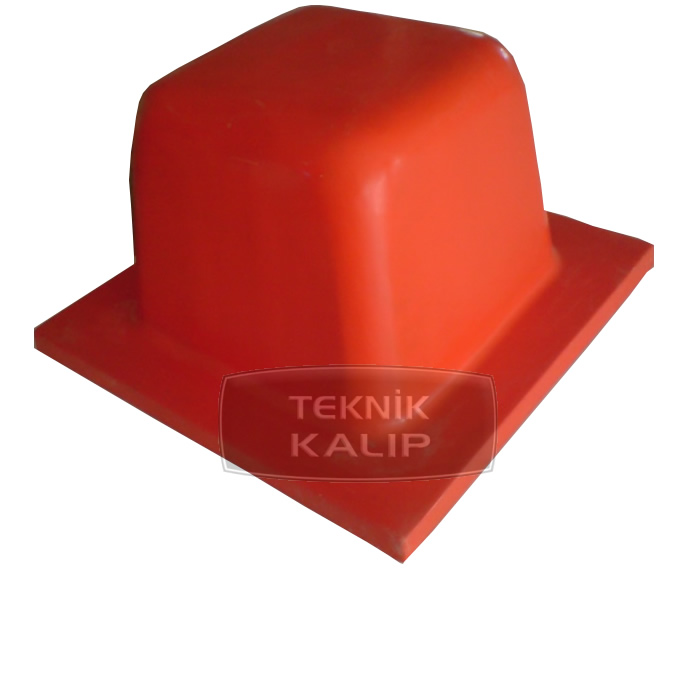

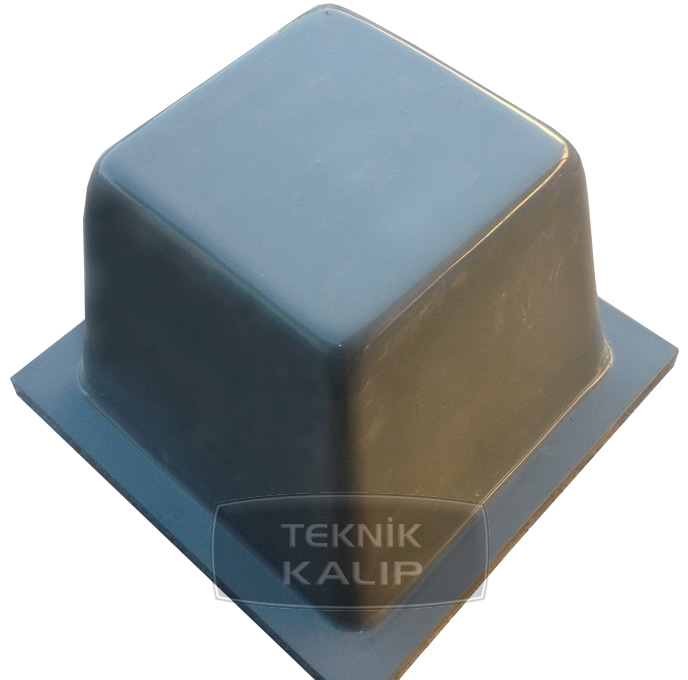

DEMOULDING PROCESS

For a good and easy demoulding operation mould release agent must be properly applied before concreting. Because of minimal bending and deformation under certain temparature and pressure when the concrete cures, demoulding operation needs the help of air pressure. This situation is not so safe like fiberglas when used any thermoplastics material in the mould. Later you can see a lot of cracks in the concrete. Operator must apply air pressure through…

More…